I am a research associate at the Munich Institute of Robotics and Machine Intelligence under the supervision of Prof. Sami Haddadin, where I investigate robot manipulation skill creation, telepresence, safe human-robot interaction, and organize robotics competitions.

Previously, I was the lead robot system integration engineer at Vicarious (acquired by Intrinsic in 2022). In 2015 I co-founded Nourish Technology where I designed and built a prototype fully automated restaurant serving breakfast sandwiches and coffee called BreakfastBox. Prior to this, I have worked as a robot system integrator for Apple, Google, Tesla, Medtronic and others providing turnkey automated manufacturing solutions. I received a bachelor of science in mechanical engineering from UC Berkeley and a masters in business administration from the Technical University of Munich.

Email / CV / LinkedIn / Google Scholar / GitHub

Previously, I was the lead robot system integration engineer at Vicarious (acquired by Intrinsic in 2022). In 2015 I co-founded Nourish Technology where I designed and built a prototype fully automated restaurant serving breakfast sandwiches and coffee called BreakfastBox. Prior to this, I have worked as a robot system integrator for Apple, Google, Tesla, Medtronic and others providing turnkey automated manufacturing solutions. I received a bachelor of science in mechanical engineering from UC Berkeley and a masters in business administration from the Technical University of Munich.

Email / CV / LinkedIn / Google Scholar / GitHub

Projects

Experience

I specialize in the design and creation of custom robotic systems to perform the dull, repetitive, and often times, dangerous tasks. My robotics journey has led me on an international career building high-reliability manufacturing lines and opened a portal into global community of machine builders. A native of San Francisco, California, I now live in Munich, Germany and seek out projects that strengthen the connection between these two innovation hubs.

Research Associate Munich Institute of Robotics and Machine Intelligence

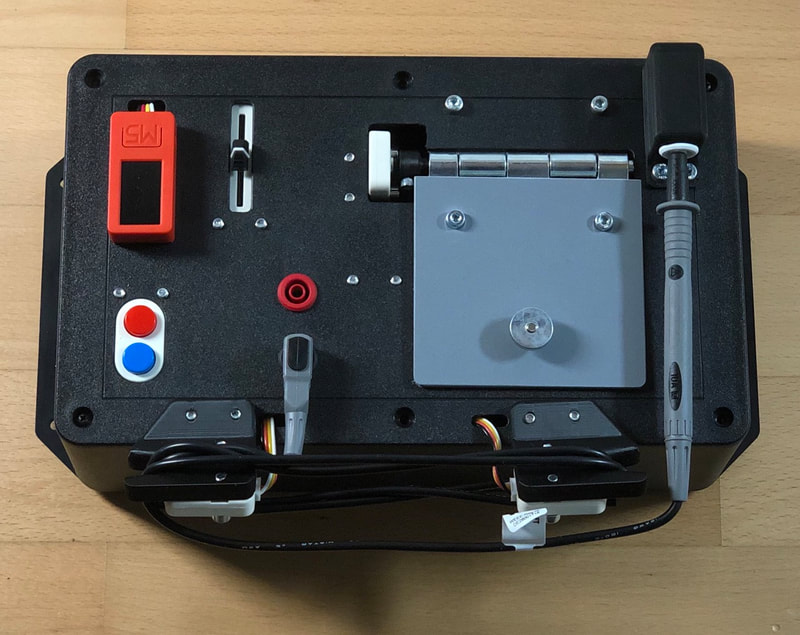

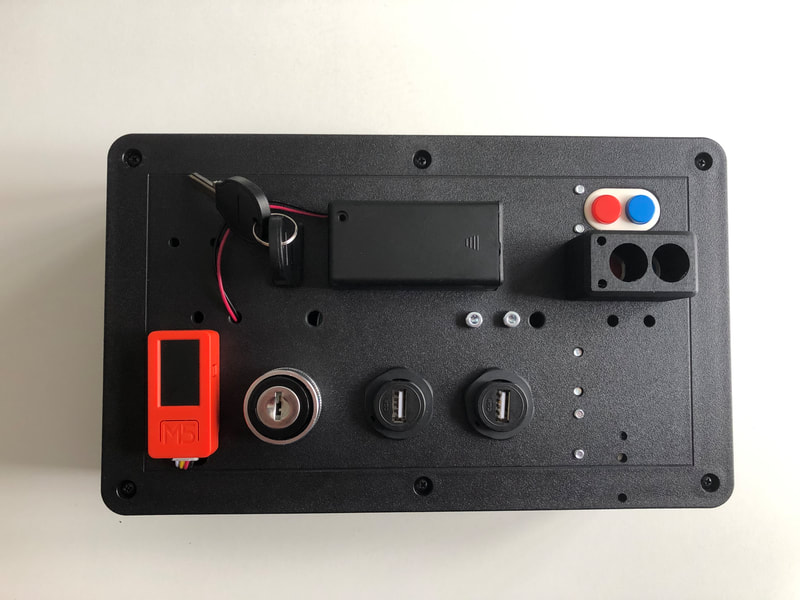

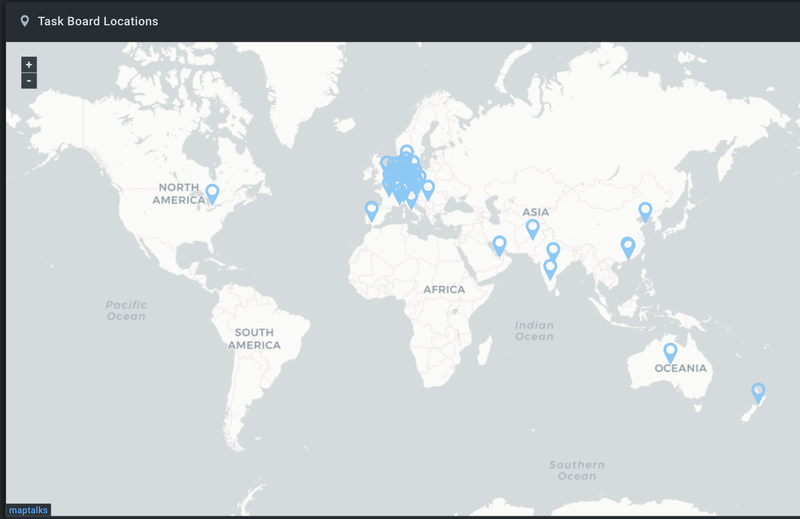

My professional curiosity led me to join the Technical University of Munich with an invitation by Prof. Sam Haddadin to study advanced robot manipulation and build robots to explore and monitor the environment. I am interested in developing telepresence robotic systems that allow the user to see but also interact with the world in a new embodiment. I design internet-connected electronic task boards to benchmark manipulation performances. I also organize the Robothon Grand Challenge competition and contribute to the EU Project: euROBIN.

My professional curiosity led me to join the Technical University of Munich with an invitation by Prof. Sam Haddadin to study advanced robot manipulation and build robots to explore and monitor the environment. I am interested in developing telepresence robotic systems that allow the user to see but also interact with the world in a new embodiment. I design internet-connected electronic task boards to benchmark manipulation performances. I also organize the Robothon Grand Challenge competition and contribute to the EU Project: euROBIN.

Lead Robot Integration Engineer Vicarious FPC

At Vicarious, I led the hardware design and implementation of standard hardware platforms for a Robots-as-a-Service (RaaS) business model. Bridging the research and product development teams, I worked with deployment to deliver new business viable robot systems to customer sites and relayed customer needs back to the product team. Vicarious developed artificial general intelligence for robots. By combining insights from generative probabilistic models and systems neuroscience, Vicarious's software architecture trains faster, adapts more readily, and generalizes more broadly than AI approaches commonly used today.

At Vicarious, I led the hardware design and implementation of standard hardware platforms for a Robots-as-a-Service (RaaS) business model. Bridging the research and product development teams, I worked with deployment to deliver new business viable robot systems to customer sites and relayed customer needs back to the product team. Vicarious developed artificial general intelligence for robots. By combining insights from generative probabilistic models and systems neuroscience, Vicarious's software architecture trains faster, adapts more readily, and generalizes more broadly than AI approaches commonly used today.

Co-Founder Nourish Technology Inc.

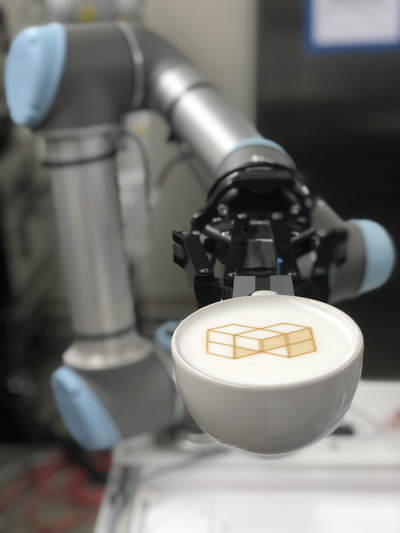

I developed the initial concept and prototype of the robotic restaurant. I established the California engineering team and built out a mock up commissary and development robotic kitchen that became the company headquarters. Nourish Technology built automated restaurants and engineered robotic systems to cook, package, and serve food and drinks. Our vision is to make high-quality, delicious, and locally sourced food and drinks accessible and affordable to everyone.

I developed the initial concept and prototype of the robotic restaurant. I established the California engineering team and built out a mock up commissary and development robotic kitchen that became the company headquarters. Nourish Technology built automated restaurants and engineered robotic systems to cook, package, and serve food and drinks. Our vision is to make high-quality, delicious, and locally sourced food and drinks accessible and affordable to everyone.

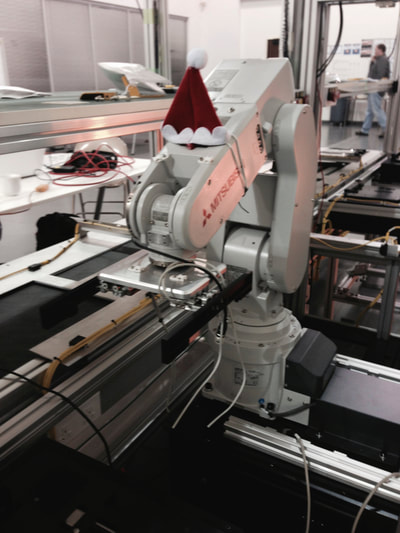

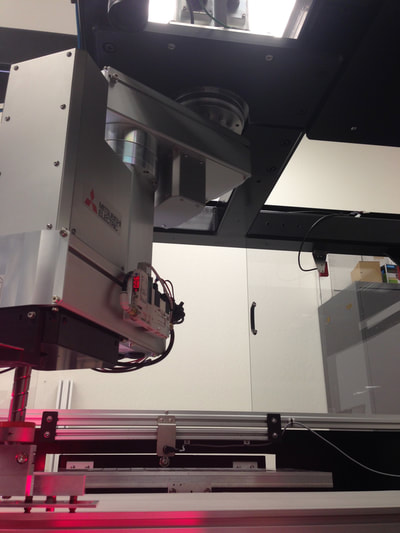

Robot System Integration/Controls Engineer L2F Inc.

I joined as the first engineer to build out the company's robot and machine vision capabilities. Here I received extensive training on vision guided robotic systems. I helped grow the team from three to fifteen and become the first RIA-certified robot system integrator in California. The Middleby Corporation acquired the company to add automation capabilities to line of food prep equipment.

I joined as the first engineer to build out the company's robot and machine vision capabilities. Here I received extensive training on vision guided robotic systems. I helped grow the team from three to fifteen and become the first RIA-certified robot system integrator in California. The Middleby Corporation acquired the company to add automation capabilities to line of food prep equipment.

Lead Project Engineer CKC Engineering, LLC

Specialized in aseptic and sterilizable manufacturing methods, I acted as a lead mechanical engineer developing mechanisms and fixtures under partner member, Chris Duggan, for the medical and pharmaceutical industries. At CKC Engineering, I received my first exposure to programming PLCs and HMIs for highly regulated process equipment. In addition, I gained hands-on experience with precision machining and equipment deployment.

Specialized in aseptic and sterilizable manufacturing methods, I acted as a lead mechanical engineer developing mechanisms and fixtures under partner member, Chris Duggan, for the medical and pharmaceutical industries. At CKC Engineering, I received my first exposure to programming PLCs and HMIs for highly regulated process equipment. In addition, I gained hands-on experience with precision machining and equipment deployment.

Manufacturing Engineer Solyndra Inc.

Charged with leading the continuous improvement of the routine maintenance of high vacuum deposition equipment, I worked with an engineering team to reduce the machine turnover time between runs from 24 hours to fit into a single 12-hour shift resulting in a daily company savings of $500,000 in operating costs. Working in the nearly fully automated factory provided me my first professional experience working with industrial robots and opened my eyes to incredible thin-film manufacturing processes.

Charged with leading the continuous improvement of the routine maintenance of high vacuum deposition equipment, I worked with an engineering team to reduce the machine turnover time between runs from 24 hours to fit into a single 12-hour shift resulting in a daily company savings of $500,000 in operating costs. Working in the nearly fully automated factory provided me my first professional experience working with industrial robots and opened my eyes to incredible thin-film manufacturing processes.